A plastic pallet mould is an injection mould utilized in developing plastic injection pallets through a plastic injection mould machine. It also has significant application in the method of production of plastic pallets. This mould contains a cavity with the same design as the required pallet and forms molten plastic around it. Some of the design specifications of the mould consist of the hot runner system that enables the injection of the plastic without difficulties.

A plastic injection mould must be used to inject plastic pallets into the manufacturing business. The plastic pallet injection mould specification is as follows: High-quality plastic injection mould from a professional mould manufacturing company like DKM where wholesale plastic pallets are produced to high-quality standards, making them reliable. The injection moulding machine ensures that the parts are accurate and uniform, delivering high-quality industrial pallets.

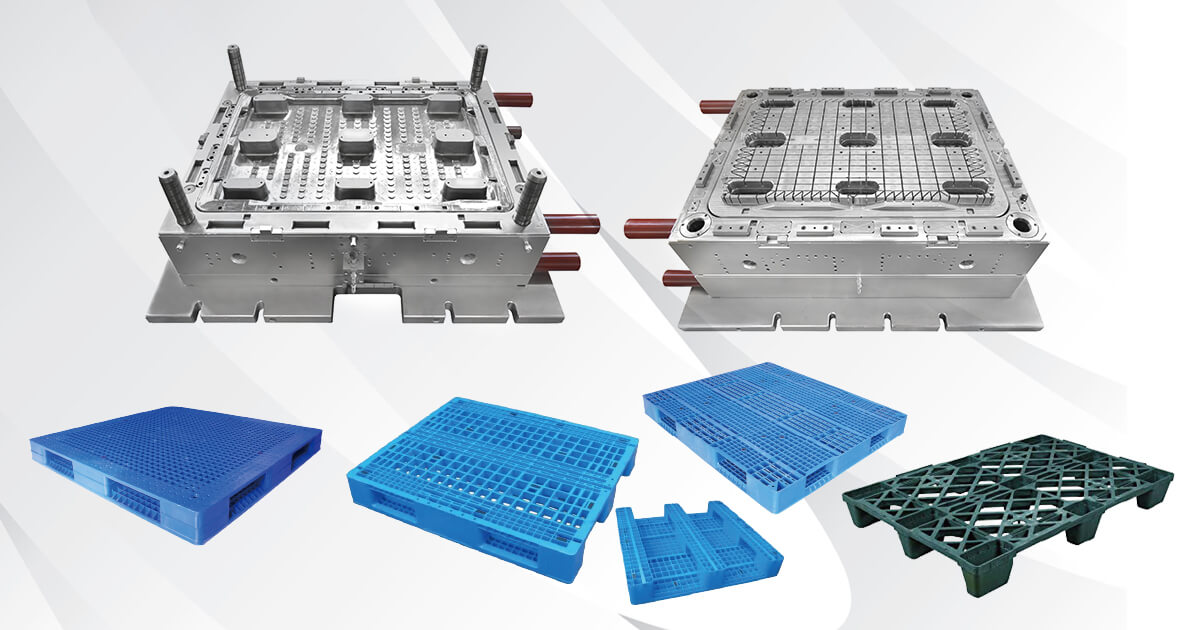

A plastic pallet moulding is, therefore, used majorly in producing pallets made of plastic. It is a mould maker custom plastic pallet solution that involves pouring molten plastic on a mould of a given shape and size to produce a plastic pallet. The role of a pallet mould is to make sure that the plastic assumes it's form that will create a strong and sturdy pallet that can be used to move and store goods in various industries. The market is stocked with different pallet moulds, for instance, the single face pallet mould, euro plastic pallet mould injection, and pallet box mould. These quality plastic pallet moulds made from pallet mould steel, also include conveyors for cooling so one can eject the products properly.

A mould-making technique is employed with the machine for coming up with a plastic pallet. Here are five easy steps involved in the production of a plastic pallet: It covers injection of the pallet material into the mould to allow cooling of the material, ejection of the pallet from the mould, cutting of the excess plastic, and lastly, checking of the pallet for quality. Companies like DKM deal in plastic pallet mould and provide a variety of euro pallet and industrial pallet mould injections for customers to select from.

You need to follow specific preparatory steps before employing a plastic pallet mould. This aims to ensure that the mold you have to use is clean and, without debris, adequate preparations of all the materials and other tools. Furthermore, it is also essential to know what the pallet mould solution and the plastic pallet mould structure look like to understand the mould's functionality.

It's also significant to note that proper blow moulding or injection moulding of a pallet mould requires a precise sequence of steps. This ranges from preparing the injection system ejector and checking on the pallet mould gate to achieving the best results. When ordering the creation of the plastic pallet mould, it is also essential to choose the right type, which can be a double-sided plastic pallet mould or even a construction of the heavy-duty plastic pallet mould.

One of the pitfalls in using a plastic pallet mould is not verifying the mould's steel hardness, which affects the pallet's strength. Another critical aspect that needs to be well done to avoid damage or a tear-off on the surface of the mould is to cover it adequately when it is not in use. Also, choosing the wrong plastic pallet mould maker or injection mould manufacturer has the effect of acquiring low-quality plastic industrial tools. By using these steps and tips, the production of high-quality plastic pallets for industrial uses would be achieved.

Using a plastic pallet mould has several advantages within a business environment, especially for manufacturing companies. Among all the mentioned benefits, this one can be attributed to cost-savings, as using a mould to make plastic pallets is considerably cheaper than the traditional methods. This is because by acquiring quality pallet moulds, firms can use plastic material to make the pallets in a larger quantity; hence the cost of production is brought down. Also, the versatility that accompanies a plastic pallet mould is that one can be made to order depending on the type of business and the standards of that business.

On top of it, the efficiency and consistency in the production we get with pallet mould increases the worth and necessity of opting for plastic moulds for manufacturing. When using the plastic pallet mould, good structural support and heavy capacity plastic are used in making the pallets. This assists in avoiding additional weight complications in transportation. This heavy-duty and high-quality plastic pallet mould is equipped with many ejector pins and gate designs, which facilitates the manufacturing of numerous forms of plastic pallet moulds to satisfy the various demands of consumers.

In maintaining a plastic pallet mould, some essential things must be done to make the mould efficient and long-lasting. To begin with, cleaning and drying of the mould should be done following the correct procedure to avoid the accumulation of residues or causing harm to the mould. Moreover, it is recommended to perform a periodic check of the mould and look for any signs that indicate wear and tear of the high-quality pin accessories so that the problem is solved immediately. Information on dealing with some of the challenges likely to manifest with plastic pallet moulds helps avoid hefty repair bills and lost manufacturing time in mould making.

Moreover, to counter this, one should consider using oversized plastic pallets that undergo heavy-duty large plastic pallet moulds, with a hint that high-density polyethene material is the best solution for the pallet for the reason that it is strong enough to endure transportation and storage processes. Particular attention should be paid to what type of product has to be palletized and the load capacity of the plastic pallet mould for specific kinds of business, for instance, food and beverages. By mainly using multi-point gates and even force distribution technology, it is possible to decrease the processing expense and manufacture the mould efficiently.

Therefore, it is necessary to highlight again the necessity of employing a plastic pallet mold in creating plastic pallets. Thus, engaging the services of an experienced plastic mould maker for a plastic pallet mould means businesses end up with solid and well-designed pallets throughout. The fact that a pallet mould is utilized enhances the ability to transport plastic pallets in a particular design or size due to the available options. Furthermore, using a plastic pallet mould can prove valuable in cutting down costs and other manufacturing procedure wastes.

Again, when it comes to using a plastic pallet mould, some essential guidelines include the moving and fixed parts. Consequently, it is recommended that the mould is well checked for signs of wear and tear to finally apply maintenance standards aimed at increasing the shelf life of the plastic pallet moulds while producing good pallets. Also, one can go deeper into knowing the single-side moulding methods and searching for the right price for the material to enhance efficiency in controlling the costs.